Our shop is fully equipped to undertake any repair.

From sound boards, pinblocks, bridges, and strings, to actions, keys, trapp (pedals), cabinet and rollers.

We stock a large variety of parts and have access to thousands more.

We also have the ability to fabricate parts that are no longer available.

We have found that most repairs can be performed on the spot in a matter of minutes. Many of these may be done at no charge if done along with another service (tuning, appraisal, etc).

Scroll down for detailed information about the components of your piano.

Vertical Piano

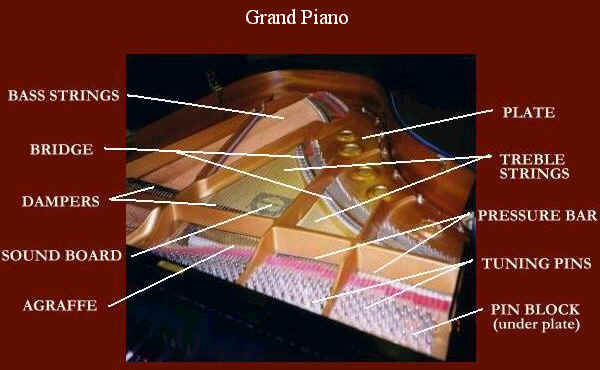

Grand Piano

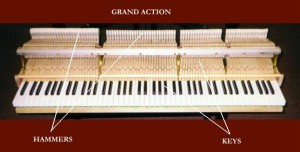

– Actions –

Actions are made up of levers, hinges (usually made of wood), felt pads and steel springs, all mounted on rails that align them properly. Each note can have as many as 20 individual pieces, all working together. The pieces have names like Jacks, Whippens, Butts, Shanks, Abstracts and etc. The hinges (called Flanges) pivot every time a note is played. Sometimes after years of use the “Centerpin” that holds the flange together can work loose and needs to be replaced with a larger one. Also the screws that mount the action parts to the rails can work loose and must be tightened. This is a vague description, however a detailed description of how actions work would be very lengthy. Considering actions can have as many as 1800 individual parts, a good piano does not require a lot of repair under normal circumstances. Hardwood “action” parts rarely break. Pianos with plastic parts should be avoided. Older plastic tends to “dry-rot”, becomes very brittle, and then breaks. Wooden “actions” can last well over 100 years with little or no breaking.

Regulation

Regulating a piano improves the “touch” of the keys and brings consistency to the volume from note to note. There are four main adjustments that can be made to accomplish this.

- “Lost motion” is movement in the key that does not result in movement in the hammer. The “keystroke” (3/8 inch) converts into the hammer stroke (as much as 2 ½ inches). As little as 1/16th inch of lost motion in the key can reduce the hammer stroke by ½ inch, thereby reducing the power of the hammer stroke from 20 to 50 percent. Adjustments are made at the back of the key.

- “Let off” determines when the jack (which pushes the hammer into the string) disengages the hammer, allowing the hammer to fall back away from the string, so the string can freely move to resonate. This adjustment is made at the bottom of the jack.

- “Back checks” catch the hammer as it falls back from the string, keeping it from bouncing back into the string. If the hammer bounces it can cause a double or triple strike on the string with one press of the key. Backchecks are on wires and are bent precisely into position.

- “Repetition levers” (Grand pianos only) When a key is depressed and held, the repetition lever must lower the jack to a position under the hammer so that the note may be played again without the key going back to its original position first. This adjustment is made behind the jack.

When all aspects of the action are in proper adjustment, each key should feel exactly the same: the same resistance, the same speed of return, and the same power produced at the point of contact with the string. It is very time consuming to regulate a piano properly. Subtle changes make a great deal of difference in the “touch” of the piano.

– Keys –

Piano keys pivot on a pin in the center. When depressed, the “keystroke” is 3/8 inch in the front and comes up 3/8 inch in the back where it comes in contact with the “action”. The front of the key is held in place by a guide pin. The keys rest on felt pads, front, back, and center. The holes in the keys that accommodate the key pins have felt bushings between the steel pins and wood keys.

Over time, the felt can wear and compress. The result may be that the keys develop a great deal of play from side to side, they may become unlevel, or the keystroke may vary. These problems can be corrected by replacing the bushings and/or inserting paper spacing washers under the keys to achieve a levelness and consistency in the keys.

Keyfaces are more of a cosmetic repair than a mechanical repair. Black keys (sharps) on older pianos are made of ebony wood. When they are worn, they can be sanded and refinished. However on newer pianos they are usually made of plastic and must be replaced when worn beyond acceptability. White keys (ivories) on older pianos were actually made of ivory from elephants’ tusks. Newer pianos have plastic keytops. If the keytops become chipped or badly discolored they can be replaced, however only in plastic. Piano keys can be cleaned in many different ways.

The best way we have found for you to clean your piano keys is a 50/50 solution of bleach and water. Dip a cloth in the solution and wring out thoroughly. Wipe keys firmly, making certain that none of the solution runs between keytops onto the wooden key. Also be careful not to drip on any carpet close to the piano.

– Felt –

Felt is used throughout the “action” and “keybed”. For instance, after a key has been depressed, when it is released, a felt pad called a “damper” pushes against the string to stop the resonance. After many years, sometimes the dampers need to be resurfaced or replaced to stop “zinging”, ringing, or non-ending resonance. Felt is also used between action parts that bump or rub each other to keep them from clicking or squeaking. Each note may have as many as twenty-eight individual pieces of felt. Moths are a natural enemy of the felt of a piano and can do a tremendous amount of damage. If a piano’s mechanism becomes loose or noisy, it is probably due to wear of the felt or moth damage. Replacing felt in an action is extremely time consuming and very costly. But with proper care, felt can last well over a hundred years

Lyres / Pedals – Most piano have three pedals. The right pedal is always a sustain pedal, which when depressed, notes played will hold until the pedal is released. The left pedal is usually a “soft” pedal. A diminished volume is accomplished by a baffle, or a shortened hammer stroke. Grand actions shift about ¼ inch. The center pedal has many different purposes on different pianos. The mechanics are simple and the repairs are usually inexpensive for any “lyre” or “trapp” (pedal) repairs.

Rollers & Cabinet – Piano rollers commonly malfunction. They support a great deal of weight, and set undisturbed for years at the time. Factors such as rust or bending can cause them to bind or freeze up, or the weight of the piano can simply break them. Rollers can be maintained by occasionally cleaning and lubricating them. If rollers must be replaced, you must use rollers specifically made for pianos. Rollers commonly available at a hardware store are not designed to support the weight of a piano. Cabinet repairs can vary from small in-home repairs to extensive structural repairs, which would require bringing the piano into our shop, depending on the extent of the damage to the piano.

Strings – Strings can last well over a hundred years if they are not subjected to a salty environment (such as near the ocean), or (moisture such as in basements or garages). Bass strings sometimes go dead, or start rattling and need to be replaced. Whenever strings are replaced, whether it is one string or all of them, it can take as much as a year before the strings will hold a “tune”. If strings become rusty and start breaking, it is recommended that you go ahead and replace all of them. It will be more cost effective and in a few months the piano will hold a “tune” again. Because it takes months for the new string to hold a “tune”, if you replace a string every now and then, you will always have “sour notes” on your piano.

Pin Blocks – A “pin block” is a piece of layered wood that the “tuning pins” fit into tightly. The layers are about 1/8th of an inch thick, and the grain alternates to insure that the pins remain tight for many years. If a pin becomes loose, you can replace it with a larger one. Pins come in six sizes. On occasion, pin blocks can crack. If this occurs, even the largest pin size will not fit tightly so the pin block must be replaced. This can be incredibly expensive. Some pianos are simply not worth that kind of expenditure.

Bridges, Pressure Bars, and Agraffes – Piano strings are secured to a “bridge” at one end, and either to an Agraffe or a pressure bar at the other end. This spaces the strings properly and creates equal string length in “unisons”. Bridges are secured to the sound board. They are made of hardwood with steel pins on which the strings are secured. Sometimes the pins can work loose or the bridge can become dislodged from the sound board. Also, the bridge can crack or split. These problems can cause “buzzing” or “rattling” when the piano is played. Some bridge repairs can be made while the bridge is in the piano. However, if the bridge must be removed or replaced, you must first remove all of the strings. This can become very expensive. Problems with pressure bars and Agraffe are very rare. On occasion, strings must be leveled at the bridge and the Agraffe or pressure bar in order to insure the hammer strikes them evenly.

Sound Boards – A sound board is a thin board that runs parallel to the strings. It covers most of the size of the piano. It is only supported on the edges. Sound boards are thin and made from very sappy and resin-filled hardwoods. They are “crowned” (thicker in the middle than on the edge). This board acts much like the body of acoustic guitar amplifying the sound of the vibrating strings. Maintenance of a sound board requires only that it not be subjected to extreme conditions, such as temperature and humidity fluctuations. Even under the best conditions, the sound board can develop hair-line cracks. These usually never cause any problems, but large cracks that go all the way through the board may create a buzzing or rattling sound when the board vibrates. This may only happen on certain notes or chords. If this occurs, cracks can be repaired. However it can take away from the tone quality of the piano. Replacing the sound board can be exceptionally expensive. Replacement requires that all tension be removed from strings and the plate must be removed, which is the same procedure used when replacing pin blocks. When such extensive rebuilding is done, you should consider replacing not just the sound board but also the pin block, strings and tuning pins as well. The result is virtually a new piano. However, only a few older pianos are worth undertaking this extensive and expensive rebuilding job.

Humidity Control Systems – Humidity affects many aspects of a piano. Excessive dampness can cause keys to stick, actions to become sluggish and heavy, and strings and pins to rust. Excessive dryness can cause sound boards, pin blocks, and bridges to crack. Also, wooden parts in actions can become brittle and break more often. Fluctuations between damp and dry conditions can seriously affect the tuning as well. Dampchaser Humidity Control Devices can help to regulate humidity levels in a piano. Dehumidifiers are tubes that extend across the piano, inside. They have a low wattage heating element that distributes dry heat evenly throughout the piano, eliminating dampness. The humidifier consists of a reservoir filled with water and a submersible element. When the climate heats the water, it creates dampness in the piano. I frequently don’t recommend the humidifier unless it is absolutely necessary. Whether used individually or together, the humidifier and dehumidifier are regulated by a humidistat.

At Conder’s Piano Service, we have been certified to install Dampchaser systems since 1978.